Propeller Testing Dynamometer

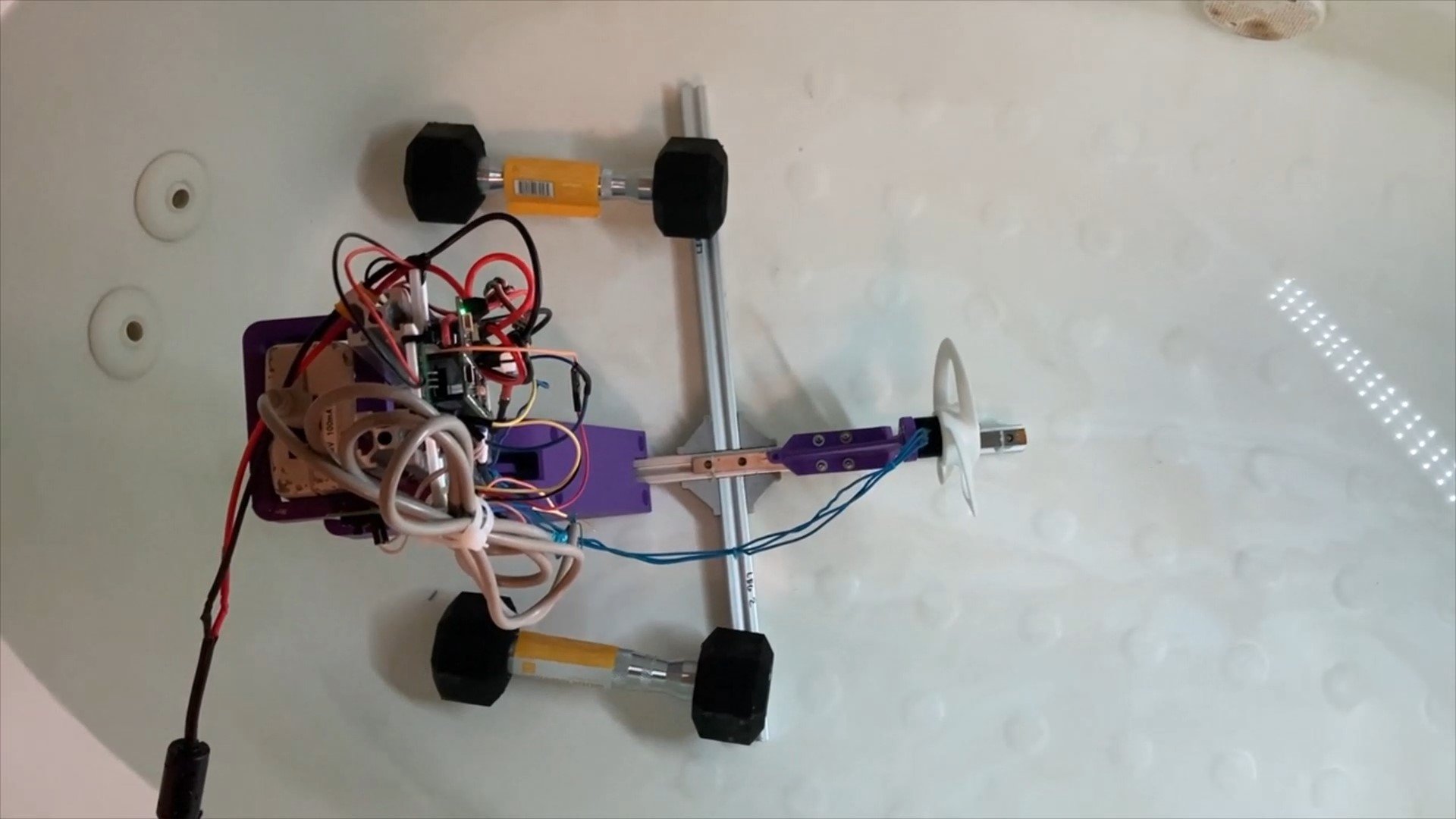

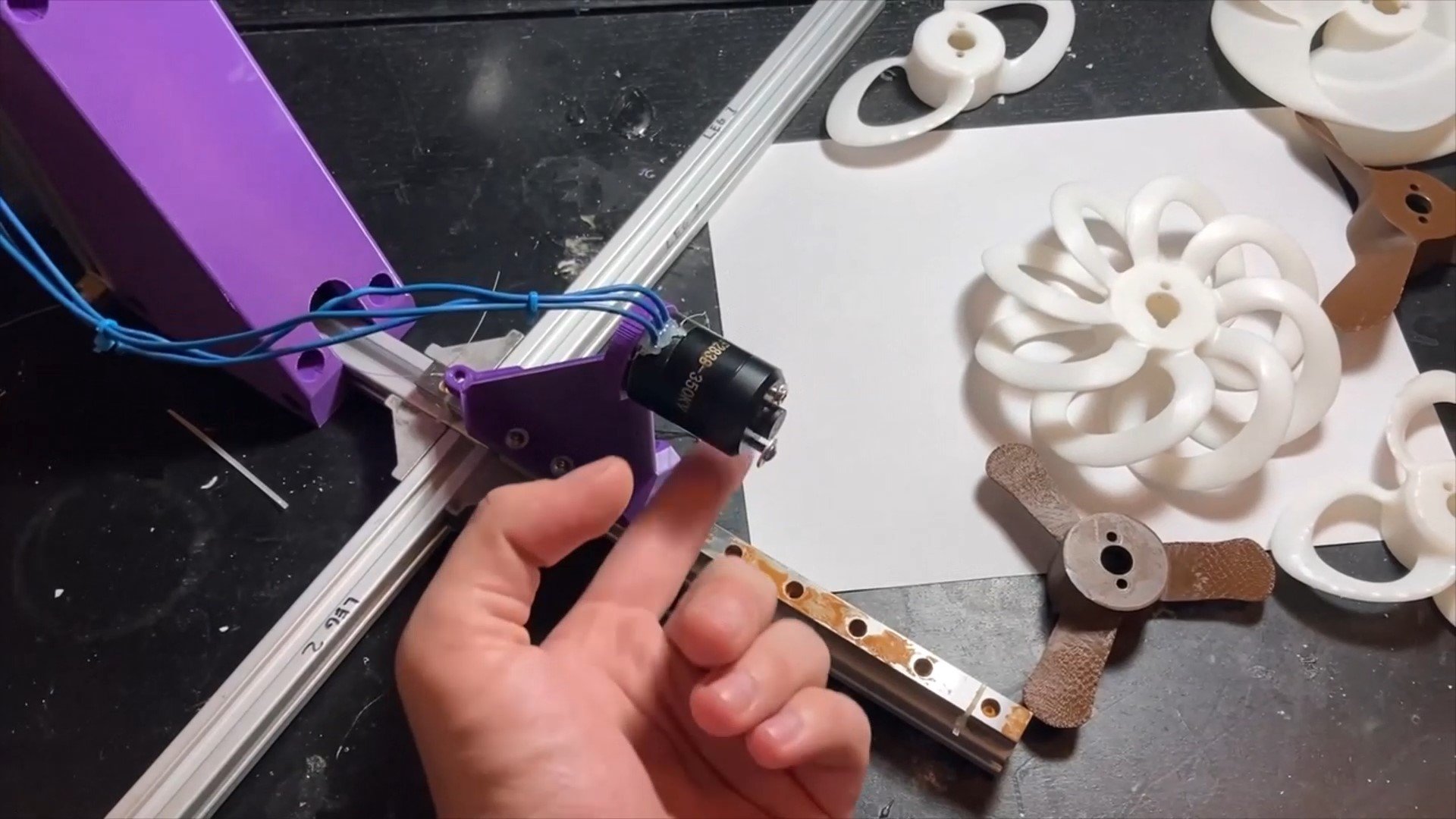

I built this machine to test my own propeller designs. The dynamometer gradually revs up the BLDC motor which drives the propeller, then gradually revs it back down while recording data to an SD card for later analysis.

The device measures prop RPM, motor current draw, and generated thrust in real time during the tests. It uses the analog output of a load cell inside a force gauge to measure thrust. An inverting op-amp paired with a mechanical torque arm improved the resolution of the force measurements.

I used this device to experiment with several propellers which I designed and 3D printed. My goal was to optimize a propeller for power efficiency to be used in my solar powered USV. I collected data from this dynamometer to find the best thrust/current draw ratio within the given power constraints of my pre-existing USV.

Project Video

This video goes through the design and build process, showing how the electronics and mechanical components of the dynamometer work. I also show the machine running and analyze some of the data it collected.

The two clear winners were propellers 4 and 5. They had by far the best thrust output in the current range I was interested in for my application (~2 amps). Many of the other propellers bogged down at higher speeds, greatly increasing current draw with diminishing returns to thrust. The toroidal propeller design is optimal for power efficiency. See the build video for further analysis of this data.

Thrust/Current Comparison For Various Propeller Designs

This rough data is a sample of what the dynamometer collected on each propeller. Note: axis labels in these graphs are not accurate due to unit conversions. I analyze this data in detail in the build video. The dyno also collected RPM data, but those measurements were a little too unreliable to be useful for analysis. The flat spots/spikes in the force charts are due to the propeller overcoming static friction and beginning to move. The flat spots in the ends of the current plots are due to the dyno program limiting the current to prevent damaging the electronics. Current would’ve continued to increase exponentially if it weren’t for the limitations of the components.